R D Group is a reputable manufacturer, exporter and supplier of vibrating screens, which are an advanced screening solutions to a large variety of industries. The vibrating screens are designed to be precise, durable and efficient: capable of separating the material better and giving a uniform performance even in challenging industrial settings.

In mining and quarrying, construction and recycling, R D Group vibrating screens provide unprecedented productivity and, therefore, cannot be ignored in your material handling and processing business.

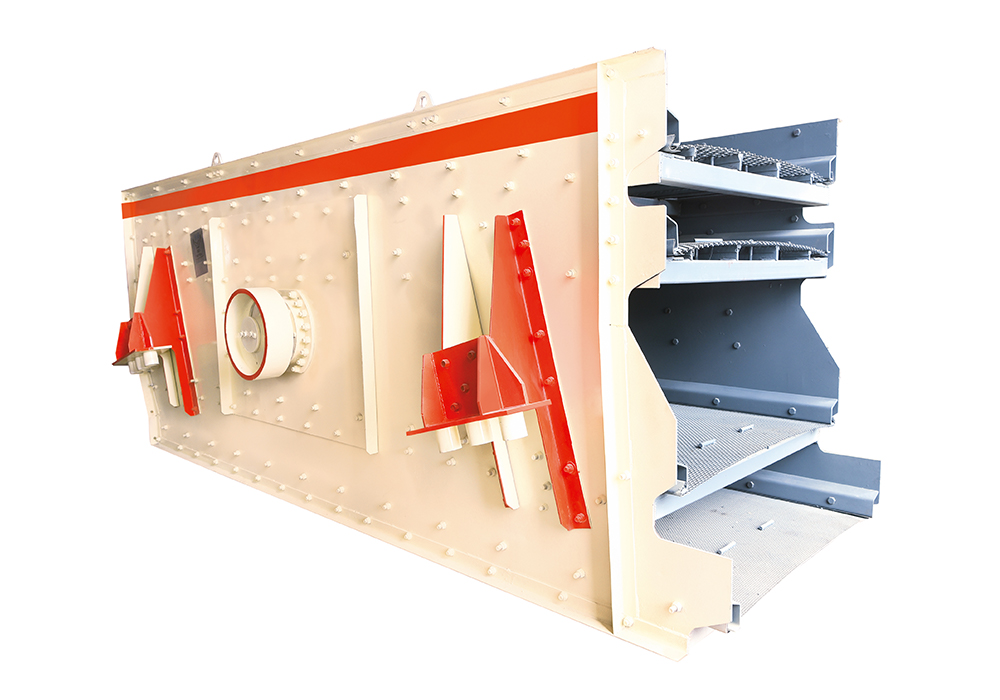

Vibrating screen is a mechanical screening machine which employs vibration in order to sort materials in terms of size. They are usually used in sorting material, size analysis, and grading of particle size in mining, aggregate, chemical, and food processing plants.

The screen mechanism works on the principle of vibrating the material over a mesh or perforated surface in order to permit smaller-sized particles to be absorbed into it and larger-sized particles to stay at the top. The vibration improves the screening efficiency and maintains the constant flow of material.

R D Group has a great variety of vibrating screens, and serves all applications, with smooth operation and a long service life.

These features make R D Group’s industrial vibrating screens ideal for both light and heavy-duty material handling operations.

R D Group’s vibrating screens are widely used across multiple sectors for their efficiency and reliability in material grading and separation:

Each vibrating screen machine is designed to deliver optimal performance under different environmental and operational conditions.

A vibrating screen separates materials based on size by using controlled vibrations, improving efficiency and ensuring accurate classification of materials.

They reduce manual labor, minimize material wastage, and enhance screening speed — resulting in faster throughput and consistent material quality.

Industries such as mining, construction widely use vibrating screens for material grading and cleaning.

While both serve the purpose of screening, a vibrating screen handles larger materials, whereas a vibro screener is typically used for fine powders and granules requiring precision.

Selection depends on material type, particle size, moisture content, and desired capacity. R D Group’s technical team can help customize the best model for your requirements.